Information

Our inner linings stand for diversity and high quality

The difference is in the details

Delivery ready for installation

In the case of made-to-measure production, there is no need for time-consuming assembly on the construction site.

Quick installation on the roof window

Our system enables roofers to install up to 15 pieces of inner lining in just one day.

Up to 15 years guarantee

We produce top quality. Since we can trust the long durability of our roof window linings based on decades of experience, we grant all customers a guarantee of up to 15 years.

Custom-fit and individual production

Orders are delivered ready for installation, all inner linings are completely pre-assembled by us. Window sills are prepared so that they can be fitted on site with little effort. Cover frames are supplied with the same frame width all round and must be fitted between rafters on site.

Short delivery time

AquaPro inner lining approx. 5-8 working days, Alpino spruce solid wood lining, real wood and lacquer lining approx. 8-15 working days (depending on the type, surface and order quantity).

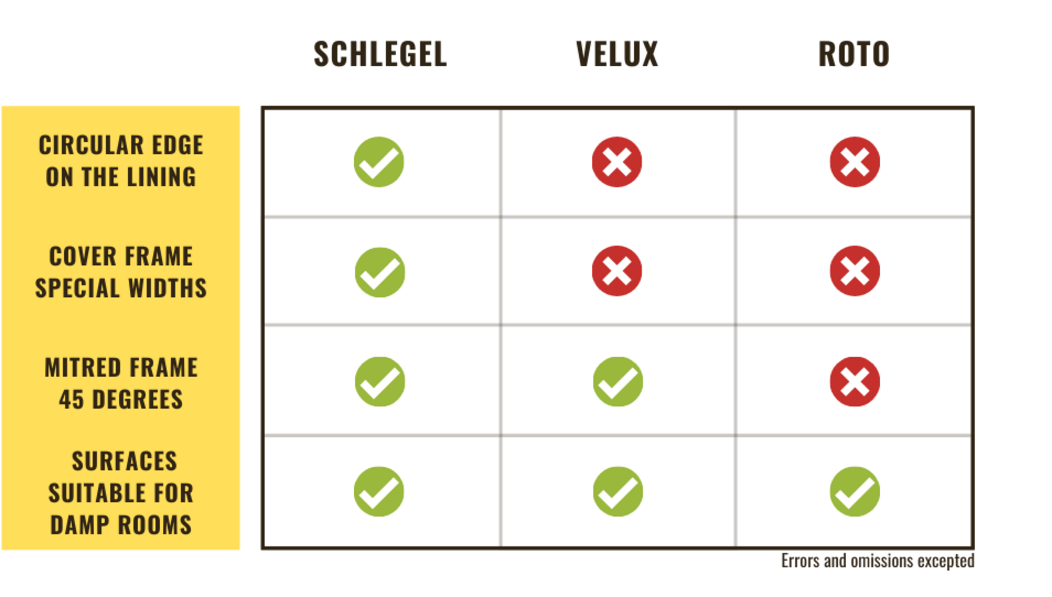

We convince with good arguments

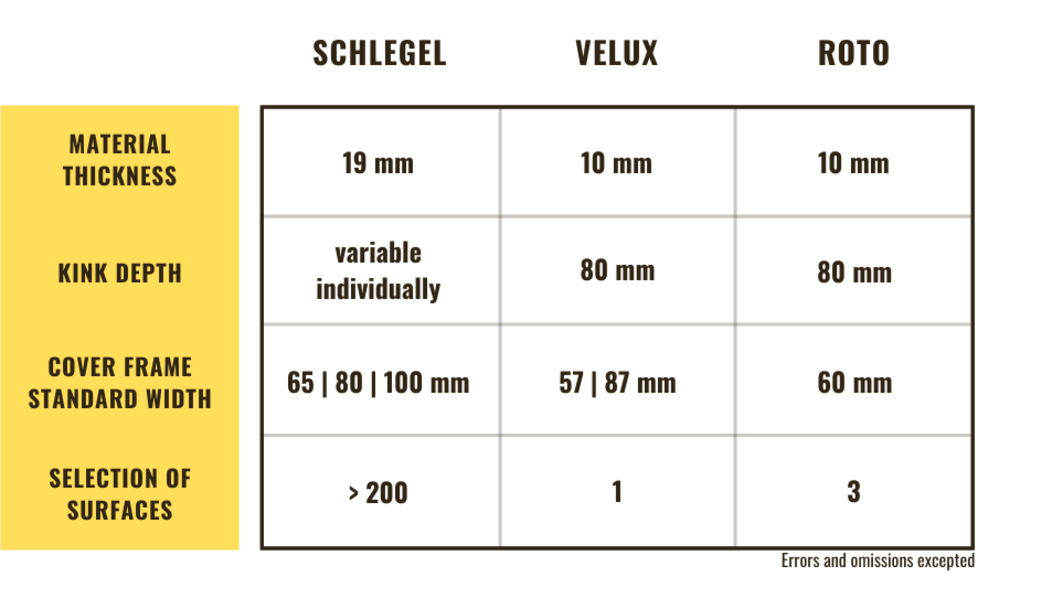

Material thickness 19 mm

We process materials with a material thickness of 19 mm, which guarantees a high level of stability and a long shelf life for our products.

Suitable for Velux, Roto, Fakro, Lideko, Heim & Haus, Braas

It sometimes happens that roof windows from different manufacturers (for example Velux and Roto) are installed on the same construction project. With our products you always have a consistent look and design of all inner linings, regardless of the manufacturer.

Our inner linings are rebated at the transition to the skylight groove and have a material thickness of 10 mm in this area, so our products fit all Velux, Roto, Fakro, Lideko, Heim & Haus and Braas skylights.

Variety of types and a large selection of surfaces

Many different types of inner lining and over 200 surface finishes guarantee a solution for your property. With us you will find the right lining for your roof window.

Cover frames in widths of 65, 80 and 100 mm, at no extra cost

Our cover frames are available for all types of inner lining in widths of 65, 80 and 100 mm at no extra cost. Individual special widths are possible up to 250 mm.

All cover frames are made with a 45 degree miter cut at the frame corners. A stable and perfect corner connection is permanently ensured by a permanent connection. Open miter joints are therefore excluded.